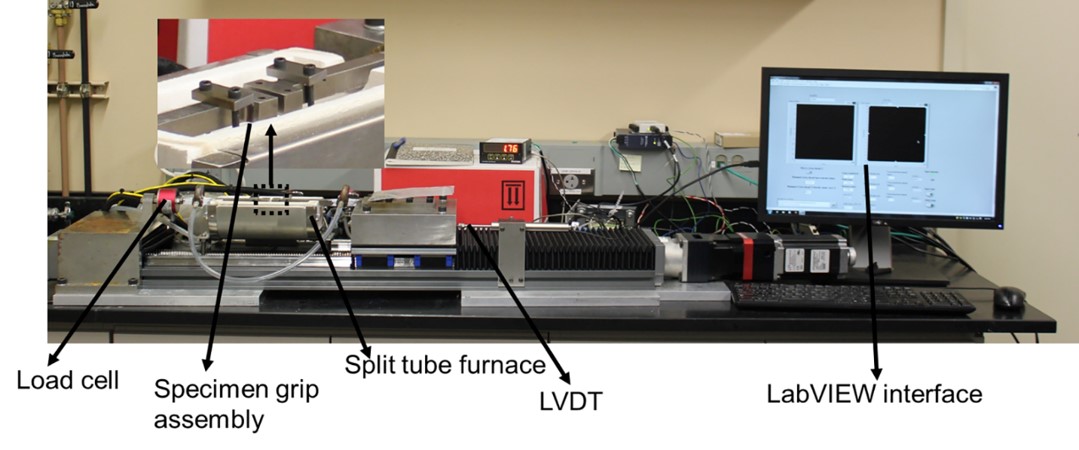

A custom-built computer controlled mini-tensile testing system is shown in the figure above. LabVIEW interface is utilized to control testing and obtain load-displacement data. Futek load cell has a maximum capacity of 500 lbs. Cross-head displacement information is obtained from linear variable differential transformer (LVDT) transducer attached to the movable head. A range of strain rates from 10-2 s-1 to 10-6 s-1 can be achieved. Furthermore, strain rate can be changed dynamically during a monotonic tensile test. The National Instruments data acquisition card is used to acquire both load and displacement information. Sample heating for high temperature testing is accomplished with a split tube furnace (ATS 3210) that is mounted around the specimen grip area. Maximum furnace operating temperature is 700ºC. These are the typical dimensions of dog-bone shaped tensile specimen: gauge length of ~2-5 mm, width of ~1-1.3 mm and thickness of ~0.5-1.1 mm.